Published on

Tuesday, July 28 2020

Authors :

Julia Tossetti and Elizabeth Hilbourn

The topic of renewable fuel feedstock always seems to generate a high level of interest, and rightfully so; the supply of it controls our ability to reduce GHG emissions. The quality and type of it guide the technologies that must process it. This second point is the topic of this week’s blog. We will cover an important quality parameter of biomass-based diesel feedstock: free fatty acid (FFA). As we weave through our discourse, we will also look at biointermediates and their potential role in the feedstock realm.

In the renewable fuel industry, FFAs are perhaps most famous (or infamous) for their detrimental effects on the transesterification process used to make biodiesel. This process involves reacting the triglycerides of the lipid feedstock with alcohol and a caustic catalyst. The products are fatty acid methyl ester (aka biodiesel) and glycerol, which is used widely in food and cosmetic applications. The effectiveness of transesterification partly depends on the FFA content of the feedstock. FFAs form when fats and oils undergo hydrolysis reactions, meaning they break down by reacting with water. If a feedstock’s FFA content elevates much above 3%, an undesired side reaction occurs whereby the FFAs react with the caustic catalyst and form soap. FFA content tends to be a concern for feedstocks like Used Cooking Oil (UCO) because the moisture from food being cooked can trigger the hydrolysis reaction that causes FFA formation. In fact, the FFA content of UCO tends to be around 15%, well above the 3% threshold. To circumvent the undesired soap formation that would happen with so many FFAs, some biodiesel producers began using a pretreatment called esterification, which converts the FFAs using alcohol and an acid catalyst. In reality, the FFA content of feedstocks can vary widely because moisture content, temperature, and storage time all affect FFA formation.

There is a section of the federal code that stipulates the renewable fuel pathways that are eligible for generating Renewable Identification Numbers (RINs) under the Renewable Fuel Standard (RFS). For the curious reader, it is Table 1 of section 80.1426. Earlier this year, the EPA made an amendment to that table so that now the biodiesel produced from esterification pretreatment as well as biodiesel made from transesterification can generate RINs. Another interesting development is under consideration: a separate pathway for standalone esterification. This would allow FFA esterification and triglyceride transesterification to happen in parallel units, resulting in both biodiesel products being able to generate RINs. Esterification has its own potential stumbling block because the acid catalysts can contribute to corrosion issues in the equipment. If this pathway is approved, it will be interesting to see what solutions materialize to overcome this catalyst challenge.

Biointermediates

The potential use of biointermediates as feedstocks is another point worth discussing. A biointermediate refers to a feedstock that has been substantially pre-processed at one facility in order to be fully processed into a final product at a different facility. Feedstocks of the cellulosic nature (i.e., woody and agricultural waste) would benefit from this arrangement because the renewable oil that they create could be further processed at various facilities to meet a diverse array of applications. These could range from renewable transportation fuels to chemicals to heating oil.

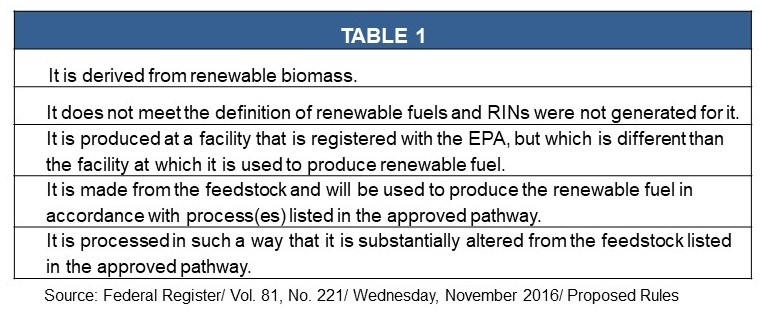

In 2016, the EPA did consider adopting regulations that would have allowed renewable fuel made from biointermediates to generate RINs. Table 1 shows the proposed criteria for biointermediates. To be categorized as such, it would have to meet all of these.

This proposal raised a number of questions concerning new regulatory requirements, hardly surprising, given the added layer of complexity that a second facility would bring in terms of oversight. For instance, the biointermediate producers would likely have recordkeeping and reporting requirements similar to those of renewable fuel producers. The EPA proposed, however, that the ability to generate RINs remain solely with the latter, reason being that it would help reduce the risk of RIN fraud. These proposals from 2016 have not yet become regulation; however, the February 6, 2020 Federal Register mentions that the provisions given in the Renewable Enhancement and Growth (REGS) proposal, which includes biointermediates, could be finalized in the future.

It is interesting to consider biointermediates in connection with our earlier discussion of FFAs. These compounds interfere with the transesterification that makes biodiesel; however, FFAs do not cause the same detriment to the hydrotreatment that produces renewable diesel because they are simply converted to paraffins (i.e. hydrocarbons). In other words, the FFAs convert to the desired product. Given these facts, one wonders if FFAs, under a future regulation, could have a role as a biointermediate: being produced by biodiesel plants, then moved to renewable diesel facilities and converted to transportation fuel. Between this possibility, and the EPA’s consideration of a standalone esterification pathway that would allow producers to further convert FFAs into biodiesel, the future may hold some neat developments for FFA usage in renewable transportation fuel.

Turner, Mason & Company has been active in the renewable diesel market for the past 10 years through single and multi-client engagements including due diligence of renewable diesel facilities. Our team is working with clients to assess renewable diesel market opportunities created by the various blending mandates, through market research offering and consulting services aimed at analyzing future supply and demand of renewable diesel, quality and sustainability of feedstock supply, and the economics driving existing plant conversions and new builds. For more information about renewable diesel market research or for any specific renewable fuels consulting engagements, please send us an email at contact@turnermason.com or give us a call at 214-754-0898.